After languishing for years outside the mainstream, “switchable glazing” is poised to become a viable alternative and could soon have a significant impact on facade design

December 2007

By Sara Hart

Most people are familiar with sunglasses that have photochromic lenses. Commercially available since 1983, the lenses darken in response to ultraviolet light and revert to clear when the exposure is removed. Though it may not seem like much of a leap from eyeglasses to windows, this technology has been slow to infiltrate the building-products marketplace.

But now it appears that both private-and government-sponsored research could soon make more energy-efficient building products widely available. One of the areas receiving considerable attention is “switchable glazing.” The National Renewable Energy Laboratory (NREL), the Department of Energy‘s (DOE) primary laboratory for renewable energy and energy-efficiency research, has focused much of its attention on windows, and with good reason. NREL reports, “Windows contribute about 30 percent to building heating and cooling electrical loads nationwide. Thus, potential energy savings from the wide-scale use of advanced windows is nearly six percent of the national energy consumption.” NREL’s research includes advanced window concepts, particularly those combining high thermal efficiency and dynamic transmittance of light. A key area of research activity is in switchable glazing, also known as “smart glass,” for a variety of residential and commercial applications. The goal is to create a viable product to control the light and gain transmittance through windows. The benefits are clear: reducing light reduces glare; reducing solar gain reduces energy costs; and controlling transparency controls privacy.

“Smart glass” and “switchable glazing” are generic terms that refer to all types of passive and active systems. Photochromic and thermochromic glazing, which are light- and heat-sensitive, respectively, are considered passive, because they do not require electricity. Those transitional sunglasses are smart, but passive. Active-control or electrochromic systems offer more options, but must be hard-wired to a power source.

Active technologies are the focus of most of the current research. Electrochromic windows are generally considered to be the most suitable chromogenic technology for energy control in buildings. They reduce or block light transmission and alter transparency in response to environmental signals, such as glare, sunlight, or temperature. The change from transparent to tinted is achieved when a small electrical current is applied to the window. The window returns to transparent when the voltage is turned off. Light transmittance during operation varies from 5 to 80 percent. Once the change in tint is initiated, the electrochromic glazing does not need constant current to maintain the tinting. In addition, the film can be tuned to block certain wavelengths, such as solar (heat) energy.

Active technologies are the focus of most of the current research. Electrochromic windows are generally considered to be the most suitable chromogenic technology for energy control in buildings. They reduce or block light transmission and alter transparency in response to environmental signals, such as glare, sunlight, or temperature. The change from transparent to tinted is achieved when a small electrical current is applied to the window. The window returns to transparent when the voltage is turned off. Light transmittance during operation varies from 5 to 80 percent. Once the change in tint is initiated, the electrochromic glazing does not need constant current to maintain the tinting. In addition, the film can be tuned to block certain wavelengths, such as solar (heat) energy.

Electrochromic windows are made up of several extremely thin plies. Darkening occurs when hydrogen or lithium ions from an ion-storage layer are transmitted through an ion-conducting layer, which, when a voltage is applied, hurls the ions into an electrochromic layer typically made of tungsten oxide. The ions cause this layer to absorb visible light, thus darkening the window’s glass. The thin plies are sandwiched between two sheets of a transparent conducting oxide material. Finally, all the layers are encased between two layers of glass. (Gasochromic windows are similar to electrochromic, but rely on diluted hydrogen in the cavity of the insulated window unit to effect color change.) The main advantage of electrochromic windows is that they typically require low-voltage power, remain transparent across their switching range, and can be modulated to any intermediate state between clear and fully darkened.

Some of the most exciting electrochromatic research is taking place at the Lawrence Berkeley National Laboratory (LBNL), another DOE agency. Tom Richardson and Jonathan Slack of the lab’s Environmental Energy Technologies Division are developing switchable-mirror (reflective) technology. By avoiding the rare earth metals originally used in metal-hydride switchable mirrors, Richardson and Slack expect to lower the cost and simplify manufacturing. Energy performance is also improved, since the new windows can reflect or transmit both visible and infrared light.

“We are working to make reflective, electrochromic windows,” explains Richardson. “These would give the user more control of the relative reflectance/transparency than is possible with gasochromic windows. Reflective electrochromic windows have several advantages relative to both the static low-E products now used in nearly all new construction and to the absorbing electrochromic windows now on the market. They can become opaque to provide privacy and control glare even in direct sun.” Because one can choose to admit or reject solar energy at all wavelengths, they offer better savings on heating, cooling, and lighting costs. They also do not get as hot in direct sunlight and, in principle, should be less expensive to manufacture.

Two other types of switchable glazing are called liquid crystal device windows and suspended particle device windows (SPD). Liquid crystal technology has been used for some time in wristwatches and is gaining popularity as privacy glazing. A thin layer of liquid crystals is sandwiched between two transparent electrical conductors on thin plastic films, and the entire device is laminated between two layers of glass. When power is off, the liquid crystals are in a random and unaligned state. They scatter light, which makes the glass become translucent, thus obscuring direct views and providing privacy. This type is used most often in interior applications, including bathrooms, conference rooms, and changing rooms in retail stores.

SPDs, on the other hand, start out dark and become transparent when voltage is applied. They are made of an electrically controlled film with a thin, liquidlike layer in which molecular particles are suspended between sheets of glass. When electricity comes into contact with the SPDs, which have a transparent conductive coating, they line up in a straight line and allow light to flow through. Once the electricity is turned off, they move back into a random pattern and block light.

While “smart glass” technologies promise to make huge contributions to efficiency, they are poised to have a tremendous impact architecturally on facade design. Most research focuses on the impact of switchable glazing on interiors because the goal is to control daylighting and heat gain. But what about the effect on a building’s exterior, especially on the rhythm of fenestration, the architectural scale, and proportion? Switchability will make these elements fluid and certainly change perception.

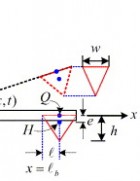

Because the use of “smart glass” is not yet widespread, the impact on design has not begun to receive much investigation. However, an experiment in the area of adaptive building envelopes is under way at structural engineer and professor Werner Sobek’s Laboratory at the Institute for Lightweight Structures and Conceptual Design at the University of Stuttgart, Germany. Of particular interest is a project called R129. “The goal of this project is to create a structure that will give the inhabitants direct contact with the surrounding nature, but still protect them from the elements,” explains Sobek engineer, Frank Heinlein.

Because the use of “smart glass” is not yet widespread, the impact on design has not begun to receive much investigation. However, an experiment in the area of adaptive building envelopes is under way at structural engineer and professor Werner Sobek’s Laboratory at the Institute for Lightweight Structures and Conceptual Design at the University of Stuttgart, Germany. Of particular interest is a project called R129. “The goal of this project is to create a structure that will give the inhabitants direct contact with the surrounding nature, but still protect them from the elements,” explains Sobek engineer, Frank Heinlein.

The building envelope is to be made of the switchable glass lites, plus a very thin layer of Plexiglas that provides antiscratch protection and has a low-E coating. These switchable lites consist of various layers, including an electrochromic foil. The foil allows the entire envelope to be darkened or made completely opaque, either in sections or as a whole. Adaptability is mainly achieved by means of the liquid crystal embedded within the glass panes, two polarization filters, and transparent electrodes. Different from other switchable-glazing product developments, this patent-pending technology allows light transmission to be varied, colorless, and quick to change.

The structural frame is fabricated from carbon box sections. The foundation is a carbon “raft,” which carries a radiant-heated floor, HVAC equipment, storage, and IT functions. There are no fixed interior partitions or walls between the various functional areas. A central nonstationary module houses bathroom and kitchen installations.

The biggest concern at the moment in all R&D is durability. NREL has been testing electrochromic devices in accordance with ASTM standard E-2141 (Standard Test Methods for Assessing the Durability of Absorptive Electrochromic Coatings on Sealed Insulating Glass Units). The lab reports that at least one manufacturer has produced a ceramic, thin-film electrochromic device that has shown excellent durability under test conditions.

According to ToolBase Services, the housing industry’s resource for technical information about building products, materials, and new technologies, the cost of electrochromic windows can be from two to three times more than a standard window. Comparing the two is not particularly useful, though, because the equation doesn’t take into account the energy savings from electrochromic insulated glass units. If electrochromic devices perform better, then a building can be equipped with smaller, and therefore less expensive, HVAC systems. At any rate, costs are expected to decrease significantly when manufacturing techniques improve and sales increase. Meanwhile, manufacturers are fine-tuning their control systems and exploring other means of powering the “smart glass.”

Return to https://cantilever.wordpress.com