2018 Update

Well she sat for a bit. I got side tracked with some other projects, but over the last few weeks I’ve been back at it a bit on the C10. Before I delve into the new stuff, I should probably catch up the blog here on how some of the earlier big pieces of the project have held up so far. Some of this is not very uplifting unfortunately – and I swear that is not because I’m a negative nelly or a difficult customer. I just rolled the dice badly on some of the folks I paid to do work. I never once complained or asked for my money back because I’m not that guy. I tried to go with the “extreme budget” option and in the end, I paid the price. If there is one lesson I’ve learned working on the truck it is that the inexpensive option is almost never a truly viable option.

Rockers and floor pans

Background: I paid a guy $600ish bucks plus the cost of the panels to replace the old floor pans and rockers and put in the new ones. This turned out to be a really big mistake. Cosmetically they are pretty bad, but considering the price, I can accept that. The part that still gets me heated is how terrible from a structural standpoint they are. The inner rockers literally fell out because they were never actually welded in to begin with. Booger welds on the rest of it with mig wire still attached, when there were any welds at all. I have no idea what I’m going to do about this long term, but eventually they will have to be replaced one way or the other. Also his shop assistant stole my license plate while it was at his shop and got a DUI. That was an interesting phone call.

Paint

Part of the truck was painted by an acquaintance at his shop. That ended up not working out too well unfortunately, but in the end I was able to get the truck back and most of the bed had been painted. The cab and doors had been painted too. The fenders, tailgate, front clip, and hood had not yet been painted. I paid up front sadly, so I lost about $3.5k on that transaction. Also unfortunately the paint has begun to form blisters in a lot of spots. I ended up painting the hood, fenders, tailgate and clip myself and repainting the cab. There are blisters in my work too in some spots, which I believe to be related to not having properly filtered and dried air since none of it appeared until it was in the heat of sun. My cut and buff job left a lot to be desired, but it was my first go at it. Eventually, I will have to strip it and start over, but hey sometimes that’s how it goes, right? I did get two new doors out of it! Live and learn!

Engine

Still going strong! It really only has about 20 hours on it so far, so we will see what the future holds. Honestly, I feel good about it! Having learned a lot more about all this in the intervening years, I have mostly pieced together the build that he went with. Its a mild build, but not gutless. Some budget parts are in there, but that’s fine for what it is. I plan on dressing things up slowly before it is all said and done. Honestly, of all the people I’ve paid to work on the truck, my engine builder is one of the only people who I feel actually looked out for me.

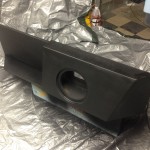

Tailgate

Tailgate repair came out pretty flawless. One thing I wish I had done is weld up the holes where the trim used to go through. I ended up trying to fill them, and you can tell where the holes were. Overall though, it looks great!

Vintage Air

Remarkably, this works! I had it charged and it blew cold. By the end of last summer, it had started to blow a little hotter, so most likely it needs charged again and has a leak somewhere, but I’ll have the AC shop figure that out. That kit turned out to be really worth it. It was a REALLY well put together kit. Very pleased.

So what does the future hold? Well, I just finished putting an AEM air/fuel gauge on in preparation for have a good friend and mentor tune the carb and troubleshoot some weirdness with the timing (that one deserves its own post). He’s a hotrodder and runs Holleys too, so it should be pretty straight forward. It’s possible he’ll be coming by tonight to get it so fingers crossed!